Aaaa

The Introduction of the Carbide Rods The Tungsten Carbide Rods, Blanks are made by Extrusion from the highest purity of ;

Basic Info.

| Model NO. | A-Carbide-05-Blanks |

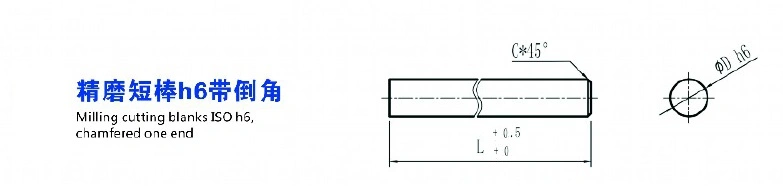

| Tolerance | H4, H5, H6, H7 Standard |

| Coolant Hole | 1 2 3 Coolant Holes, Sraight or Helical |

| Grinding Machines | Imported Centerless Grinding Machines |

| Usage | End Mills, Drill Bits, Reamers, Taps, Punches |

| Grade | Submicron, Micron, Ultra Fine, Nano Grain Size |

| Produdction Method | Extrusion or Cold Isostic Pressing |

| Length | Full Length 12", 13", 14", 300mm,310mm, 320,330 |

| Grinding | H6 Ground |

| Surface | Sintered |

| Transport Package | Standard Packing for Cemented Carbide Rods |

| Specification | CARBIDE RODS DIA 0.5 to 50 mm |

| Trademark | RYDMET CARBIDE |

| Origin | China |

| HS Code | 82090030 |

| Production Capacity | 20 Tons/Month |

Product Description

The Introduction of the Carbide Rods

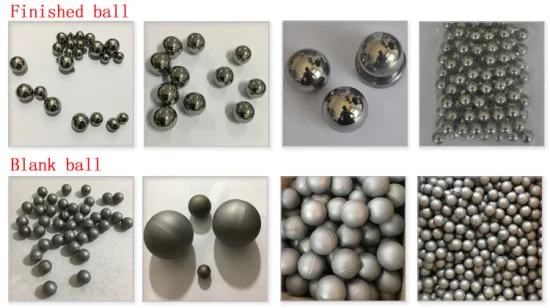

The Tungsten Carbide Rods, Blanks are made by Extrusion from the highest purity of Materials and Sinter Hiped. Be of very high quality and tool peroformances, the grade for Cutting tools are usually in Sub-micron Grain and Ultra-fine Grain. As demand,the other grade can be custom-made. They are ideal materials for the Solid rotoary Cutting tools, like Solid Carbide Endmill, Drills, Remaers, Taps.etc. Usually, the carbide rods are in sintered conditions, but we can arrange the grinding process as per the clients specific demand. Our grinding are done by the Imported Centerless grinding Machines, we can meet the precision demand of our cleints from both Europe and American, usually, we control them in h6 finsihing, as demand, we can control it be h5, h4, h7. We can even grind the Cemented carbide rods even in 0.3 mm diameter if you have. The Grades for the Carbide Rods:

| The Grade of the Tungsten Carbide Rods | |||||

| Properties of Grade | RD10F | RD10UF | RD12UF | RD06UF | |

| Co | % | 10 | 10 | 12 | 6 |

| WC incl. Doping | % | 90 | 90 | 88 | 94 |

| Density | g/cm3 | 14.45 | 14.45 | 14.1 | 14.9 |

| Vickers Hardness HV30 | kg/mm2 | 1580 | 1790 | 1690 | 1890 |

| Rockwell Hardness HRA | ISO3738 | 91.8 | 92.5 | >92.5 | 93.5 |

| TRS | N/mm2 | 3800 | 4000 | 4000 | 3900 |

| Porosity | A | < 02 | < 02 | < 02 | < 02 |

| B | 0 | 0 | 0 | 0 | |

| C | 0 | 0 | 0 | 0 | |

| WC Grain Size | μm | 0.8 | 0.5 | 0.4-0.5 | 0.5 |

Cut to Length Standard Carbide Rods, Tools Blanks

| Product No | Dia mm | Length mm | Product No | (Dia.) mm | (L) mm | |

| 0-2.35-445-G | 2.35 | 44.5 | 0-6.5-074-G | 6.5 | 74 | |

| 0-2.35-450-G | 2.35 | 45 | 0-7.0-060-G | 7 | 60 | |

| 0-3.0-038-G | 3.0 | 38 | 0-7.0-080-G | 7 | 80 | |

| 0-3.0-046-G | 3.0 | 46 | 0-7.5-074-G | 7.5 | 74 | |

| 0-3.0-050-G | 3.0 | 50 | 0-8.0-060-G | 8 | 60 | |

| 0-3.0-052-G | 3.0 | 52 | 0-8.0-064-G | 8 | 64 | |

| 0-3.0-061-G | 3.0 | 61 | 0-8.0-075-G | 8 | 75 | |

| 0-3.0-065-G | 3.0 | 65 | 0-8.0-080-G | 8 | 80 | |

| 0-3.0-070-G | 3.0 | 70 | 0-8.5-079-G | 8.5 | 79 | |

| 0-3.0-070-G | 3.0 | 75 | 0-9.0-067-G | 9 | 67 | |

| 0-3.0-070-G | 3.0 | 100 | 0-9.0-084-G | 9 | 84 | |

| 0-3.5-055-G | 3.5 | 55 | 0-9.5-084-G | 9.5 | 84 | |

| 0-3.5-070-G | 3.5 | 70 | 0-10-066-G | 10 | 66 | |

| 0-4.0-070-G | 4.0 | 40 | 0-10-070-G | 10 | 70 | |

| 0-4.0-051-G | 4.0 | 51 | 0-10-073-G | 10 | 73 | |

| 0-4.0-055-G | 4.0 | 55 | 0-10-075-G | 10 | 75 | |

| 0-4.0-058-G | 4.0 | 58 | 0-10-090-G | 10 | 90 | |

| 0-4.0-075-G | 4.0 | 75 | 0-10.5-089-G | 10.5 | 89 | |

| 0-4.0-080-G | 4.0 | 80 | 0-10.5-095-G | 10.5 | 95 | |

| 0-4.5-058-G | 4.5 | 58 | 0-11-095-G | 11 | 95 | |

| 0-4.5-062-G | 4.5 | 62 | 0-12-075-G | 12 | 75 | |

| 0-4.5-080-G | 4.5 | 80 | 0-14-075-G | 14 | 75 | |

| 0-4.5-086-G | 4.5 | 86 | 0-14-082-G | 14 | 82 | |

| 0-5.0-050-G | 5.0 | 50 | 0-14-085-G | 14 | 85 | |

| 0-5.0-062-G | 5.0 | 62 | 0-15-092-G | 15 | 92 | |

| 0-5.0-066-G | 5.0 | 66 | 0-16-082-G | 16 | 82 | |

| 0-5.0-075-G | 5.0 | 75 | 0-16-089-G | 16 | 89 | |

| 0-5.0-086-G | 5 | 86 | 0-16-093-G | 16 | 93 | |

| 0-5.0-093-G | 5 | 93 | 0-18-084-G | 18 | 84 | |

| 0-5.5-066-G | 5.5 | 66 | 0-18-093-G | 18 | 93 | |

| 0-5.5-093-G | 5.5 | 93 | 0-18-130-G | 18 | 130 | |

| 0-6.0-050-G | 6 | 50 | 0-20-093-G | 20 | 93 | |

| 0-6.0-054-G | 6 | 54 | 0-20-100-G | 20 | 100 | |

| 0-6.0-060-G | 6 | 60 | 0-20-105-G | 20 | 105 | |

| 0-6.0-066-G | 6 | 66 | 0-20-130-G | 20 | 130 | |

| 0-6.0-075-G | 6 | 75 | 0-25-074-G | 25 | 74 | |

| 0-6.0-080-G | 6 | 80 | 0-25-125-G | 25 | 125 | |

| 0-6.0-093-G | 6 | 93 | 0-25-150-G | 25 | 150 | |

| 0-6.5-070-G | 6.5 | 70 | 0-25-170-G | 25 | 170 |

You may also like

Send inquiry

Send now